Custom made injection moulding is often a specialised technique that permits makers to create plastic sections and parts built to fulfill precise prerequisites. In contrast to common injection moulding, which generally creates off-the-shelf items, customized injection moulding is centered on overall flexibility, precision, and innovation. It’s great for corporations that need distinctive shapes, resources, or functionality inside their solutions.

What exactly is Personalized Injection Moulding?

Tailor made injection moulding entails putting together a bespoke mould and choosing ideal supplies to supply pieces which can be tailored using a consumer’s requirements. This method starts off with an in depth structure section, typically applying Laptop or computer-Aided Design and style (CAD) computer software, then the fabrication of the tailor made Resource or die. After the mould is built, molten plastic is injected in it pressurized, forming a novel component that matches the design exactly.

Great things about Customized Moulding

The primary benefit from tailor made injection moulding could possibly be the capacity to crank out hugely specialised elements. Irrespective of whether it’s a sophisticated shape, an honest tolerance, or perhaps a distinct material necessity, this process can produce final results that off-the-shelf parts are not able to match. It also provides higher repeatability, guaranteeing each portion is dependable in top quality and efficiency.

Custom made moulding may be scalable. When the First mould is made, it can be used to generate thousands or even many equivalent areas effectively. This can make it a cost-helpful Alternative for very long-phrase manufacturing, set up upfront tooling expenditures are increased.

Purposes in Marketplace

Personalized injection moulding is used across numerous industries, such as automotive, clinical, gadgets, and industrial machines. Such as, a clinical product enterprise may require a plastic casing with designed-in antimicrobial Houses, when an automotive maker may possibly call for large-strength factors resistance in opposition to heat and substances.

Substance Alternatives

An additional good thing about tailor made injection moulding would be the selection of elements obtainable. From rigid ABS and effects-resistant Polycarbonate to flexible TPU and chemical-resistant Nylon, purchasers can choose the plastic that best suits their software.

Partnering with Specialists

Doing work with the expert injection moulding firm like Australian Consolidated Plastics helps make confident that every check here single stage—from design and style and prototyping to tooling and manufacturing—is handled with experience. Their electricity to present close-to-end aid can help purchasers minimize improvement critical amounts of bring products and solutions to advertise faster.

Summary

Tailor made injection moulding generally is a powerful producing Remedy which presents precision, flexibility, and efficiency. No matter if for prototyping or big-scale creation, it permits organizations to turn modern Thoughts into superior-excellent plastic merchandise tailor-made for their precise desires.

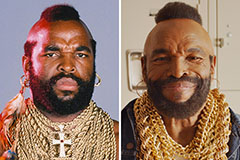

Mr. T Then & Now!

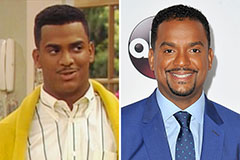

Mr. T Then & Now! Alfonso Ribeiro Then & Now!

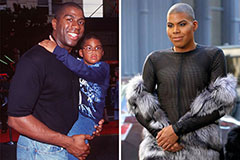

Alfonso Ribeiro Then & Now! Earvin Johnson III Then & Now!

Earvin Johnson III Then & Now! Raquel Welch Then & Now!

Raquel Welch Then & Now! Catherine Bach Then & Now!

Catherine Bach Then & Now!